OUR SUSTAINABILITY MISSION:

We’re focused on keeping plastic and other disposable items out of people's hands and ultimately the ocean. As we evolve as a business and a brand, one thing remains at the forefront - providing as much transparent information as possible while thinking about all things related to helping Mother Earth.

IT STARTS AND ENDS WITH THE OCEAN.

At BYBBA, the ocean runs deep throughout our process and our purpose.

And now, we’re taking our commitment one step further in fighting the global plastic crisis as we introduce a dynamic partnership with 4Ocean,

With every BYBBA bag purchased, we’re funding the removal of one pound of plastic from oceans, rivers, and coastlines. Our goal is to leave the planet better off than when we started, keeping our oceans clean for generations to come, one bag at a time. We’re creating ways to reduce, re-use and, now, reward with every purchase.

4Ocean oversees daily cleanups around the world, creating jobs for people living in communities impacted by plastic pollution, and inspiring action on behalf of our one shared ocean. Our impact giving is a direct donation made with every purchase that goes directly toward their efforts and infrastructure. To learn more about 4Ocean visit the 4OCEAN WEBSITE.

HERE'S A BREAKDOWN OF OUR PRODUCTS, HOW THEY STACK UP AND.... HOW THEY BREAKDOWN.

PACKAGING: Our packaging is 100% recycled and recyclable. We hope you’ll find continued uses for it-future gifting, storage or shipping.

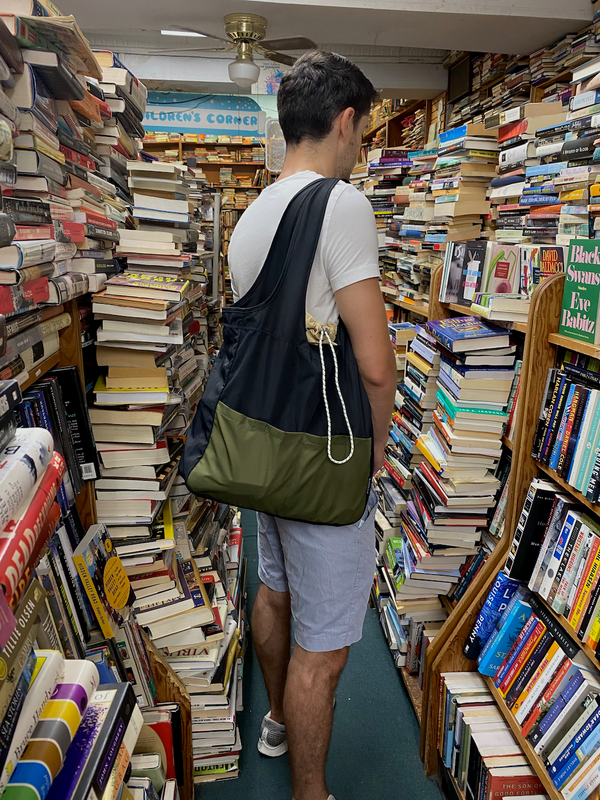

WHAT WE'RE MADE OF: The Balos is made from 100% post-consumer recycled plastic that’s crushed into billions of miniscule chips, and then washed until they’re sparkling clean to create our Techniluxe™ fabric. This includes mainly plastic water bottles but also much of the plastic debris collected from the ocean and found on beaches which was important to us. Our goal was to innovate a product that felt rich and didn’t sound or look crunchy and, most importantly we thought about where it came from and where it would go next. It had to be completely recycled- 100%. We reviewed hundreds of swatch variations to get to where we landed.

The two ropes used on The Balos are made from regenerated nylons including fishing nets which, along with our bags, are constructed at our BSCI certified factory in Shen Zhen, China.

Finally, it’s also worth pointing out that our design team considered the most efficient way to construct the Balos. We worked with an experienced technical designer and challenged her with how to use the least amount of fabric and find uses for any excess. Then, when it comes to production, the bags are machine-bound, resulting in the least scrap waste during the process.

HOW DO WE TRUN OLD PLASTIC INTO BAGS?

Did you know almost all synthetic bags are made from plastic? We just make ours with materials that would otherwise clog landfills, drift in the ocean and pollute beaches. It all starts with 100% post-consumer plastic that have labels removed, are crushed into billions of tiny chips, and then washed until they’re sparkling clean.

After a bunch of science stuff with names like “polymerization,” you get a soft, recycled yarn that eliminates the need for petroleum and diverts water bottles and other plastics from landfills at the same time.

WHERE DO WE MANUFACTURE?

All of our textiles are made from recycled materials in our facility in Taiwan that specializes in eco-friendly and high-quality textiles, then cut-and-sewn in one of our partner facilities carefully chosen for their values and ethics. Our main factory is located in Shen Zhen, China and BSCI certified across a long list of employment and social guidelines, most importantly guaranteeing fair wages, safe and healthy conditions, and zero forced or child labor.

WHY CHINA AND NOT THE USA?

You may not know it, but a lot of the best manufacturers for high-performance fabrics are located overseas. We know - we looked. The United States has great manufacturers for basic knitwear, but for our bags the best machines up to the challenge and scale were in China. Once we found our certified manufacturer, we knew it was a match. Quality is everything to us, and we wanted to make sure we gave you the best product at the best price that you could find.

HOW DO YOU KNOW WE'RE REALLY FAIR TRADE, AND USING RECYCLED FABRICS?

We want to be as transparent aas possible, so we're happy to share our certifications with you. Our factory is BSCI certified, which promises that our operation adheres to super strict regulations that keep factory employees well-paid, safe, and living healthy lives.

Our recycled fabric is certified Standard 100 by Oeko-Tex, a world leader in testing fabrics to regulate harmful substances. They make sure every fabric’s origin and contents are totally up front, so you know exactly what you’re buying.

WHAT DO WE DO ABOUT MICROFIBERS?

Did you know all synthetic fabrics shed tiny pieces of plastic called microfibers in the wash? We recommend wiping your Balos bag but if you choose to throw in the machine, we recommend washing all of your synthetics in a washing bag or attaching a filter. We also recommend one that attaches to your home washing machine and captures these fibers before they can enter water streams, keeping microfibers out of the oceans and away from the creatures that inhabit them.

HOW DO WE DYE?

Our fabric is dyed with eco-friendly dyes and the wastewater is carefully cleaned before it is released. The unique dyeing process can result in some irregularities in color, which are not considered damages. Please note colors may run when first washed, so we recommend washing your new bags separately or with similar colors just in case.

HOW OUR FABRIC GETS MADE...

As soon as our spinning mill takes the delivery of our raw PET chips from the recycling center, the bags of chips go through another wash, and are dried. Once they dry, the chips get sent to storage silos and are sent to a machine where the chips get heated up and extruded into long thick spaghetti like strands. From there, they are chipped down to little pellets.

The pellets then get reheated and are extruded again to make superfine threads that are spun together into our yarn. From there they are spun onto large bobbins, packaged, and sent to our knitting factory.

Our process is unlike almost anything in the industry and the end product is Techniluxe™.

Our fabric is softer, more stable and less crunchy than the standard nylons that show up on other bags. This process requires time and precision, which we feel is worth every minute!

NOW THATS SLOW FASHION!

Once our fabric is woven, it gets sent to our dye house.

The dyeing process is often environmentally destructive, with many facilities opting for non-eco-friendly dyes and chemicals, and choosing to dump wastewater freely into water sources like streams and rivers. If you look at photos of rivers that flow by cities involved in garment manufacturing, you will often notice bright blue or red water that enters the water tables that the community uses. This water not only damages the environment but is extremely harmful to people and crops that depend on their water sources to survive.

We’re very proud of how we’re handling with waste. Every single drop of water that is used to dye our fabric gets sent to our wastewater treatment plant literally 100 feet away from the machines.

There, the water gets treated to separate out our OEKO-certified safe dyes and stray fibers. When everything is separated, we measure the water to make sure it’s safe to release. The devices that measure this are set up to send information in real time to the Taiwanese EPA. With their approval, we discharge the water into a healthy stream where it goes on its merry way.

From fiber to fabric, we need to look at every step and make sure we know its impact.

TECHNILUXE™- EXCLUSIVELY OURS & A CUT ABOVE

Every year, millions of marine animals – like sea turtles, seals, dolphins, and whales – are harmed by ocean plastic pollution. About 10% of the estimated 14 billion pounds of trash discarded in the ocean annually is made up of abandoned, lost, or discarded fishing gear.

That’s why we make our bags with with Techniluxe™, a fiber we worked hard to innovate and made from 100% recycled materials and other plastic waste that would otherwise be discarded into oceans and landfills. When we founded BYBBA, one of our biggest goals was to create a fabric that was 100% sustainable from end to end with the added benefits of a luxurious look and feel that also defied the hard and noisy hand feel associated with so many other brands. And we looked beyond canvas (which requires over 650 gallons of water to create one single tote bag) and went on to test different combinations of crushed plastic pellets until we came up just the right eco-cocktail.

By using recycled material, we help clean our oceans, recycle that waste, and cut out the need for raw materials like crude oil, which are traditionally used in the production of nylon.

300 swatches and 42 blind touches later, we landed on Techniluxe™, our exclusive fabric woven entirely from post-consumer recycled plastic. Unlike other sustainable options, we developed Techniluxe™ in 103 vibrant-rich colors and a unique soft, matte texture that feels as good as it looks.